TECHAGRO

30.3. - 3.4. 2014

International Fair of Agricultural Technology

Dieci 40.7 VS AGRIPLUS

| PROFILE OF EXHIBITS | |

| Product: | Dieci 40.7 VS AGRIPLUS |

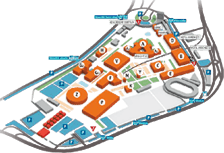

| Location: | Hall P, st. 014 |

| Producer: | Dieci S.r.l |

| Exhibitor: | MANATECH CZ s.r.o. |

Brief characteristics of the exhibit

Brief feature of the exhibit

Telescopic handler Dieci AgriPlus is produced by the company Dieci. The main area of use of this machine is the agricultural business. The capacity of this machine is 4 tons and the lifting height is 7 meters. This machine is equipped with a one man wide cabin. A diesel engine placed at the side of the machine, creates the energy which is used for both the drive line and the movement of the handling parts of the machine. The machine is equipped with so called vario system of drive line which contains one hydrostatic pump with variable displacement, one hydrostatic motor with variable displacement, one hydrostatic motor with fixed displacement. Both axles are driven and can be equipped with limited slips. Both axles are steerable and the machine allows choosing among the front axle steering, both axles steering or diagonal steering. The gear pump with maximum capacity 210 l/min. runs all hydraulic functions (handler boom up, down, telescopic boom out or in, implement carrier forward, reverse). Thanks to the unique drive line system the driver of the machine can choose one of 4 different drive modes which are the best for pilling, barn work, trailer pulling, and fast transport to the other place. The modes are: automotive mode, loader mode, eco mode and creeper mode. The machine is equipped also with an inching pedal which allows exact and gentle movement if wanted. Thanks to the totally new drive line the machine offers the “best in class” consumption of fuel.

Specification of advantages compared to the competitors

Specification of advantages of the telescopic handler Dieci AgriPlus 40.7VS.

1. Totally new vario system of the telescopic handler drive line enables the choice of 4 different operational modes according tot he demands of the job which is being run. This system contains the hydrostatic generator with variable displacement and 2 hydrostatic motors. One of them is also with variable displacement and both are working independently. This is the first time when this system is used at any of telescopic handlers at all. It is developed to reach higher speed (40km/h) and to maintain the high traction force. This system reduces the consumption of fuel for 20% comparing to a hydrodynamic system of the drive line.

2. Entirely new safety hydraulic valve (lock) allows the descent of the boom when the engine is at idle speed (800 rpm) as fast as the other valves allow when the engine is at max. speed (2200 rpm). This increases the working speed and reduce the consumption for 7-8%.

Photo