TECHAGRO

3.-7.4. 2016

International Fair of Agricultural Technology

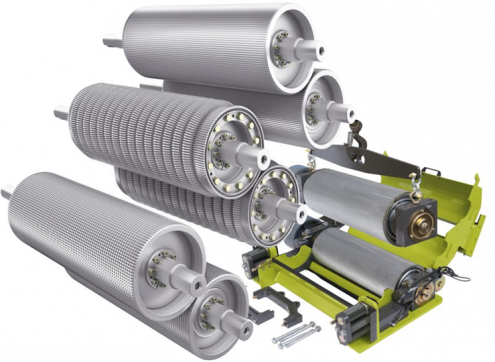

CLAAS MULTI CROP CRACKER MAX

PROFILE OF EXHIBITS

| Product: | CLAAS MULTI CROP CRACKER MAX |

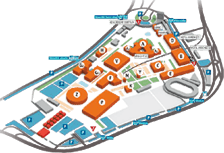

| Location: | Hall F, st. no. 015 |

| Producer: | CLAAS KGaA mbH |

| Exhibitor: | AGRALL zemědělská technika a.s. |

Brief characteristics of the exhibit

It follows that farms or contractors who have to meet very diverse requirements require a particularly flexible solution. Whether using a long or short-chop configuration, the aim is to produce forage which meets the highest standards with regard to kernel processing across the widest possible dry matter and chop length range. In order to cater for these requirements, CLAAS has extended its range with the new MULTI CROP CRACKER MAX. The MCC MAX can be used across a wide chop length range from 7 to 22 mm, as well as in the usual dry matter content range from 27% to 50%. As a result of the more intensive processing, it is possible to chop material that is up to 50% longer in order to obtain sieve fractions comparable to those produced by a conventional corncracker. In this way, farmers who supply dairy cattle and biogas facilities with material from the same clamp can produce silage with an optimal structure for both applications.

Specification of advantages compared to the competitors

The MCC MAX is a new conditioning system for maize silage in the JAGUAR forage harvester. The MCC MAX corn cracker rollers have been developed for conditioning maize silage with chop lengths of between 7.0 and 22 mm, which is the most popular application range. They have a sawtooth profile and each feature 30 annular segments. The positioning and special geometry of the annular segments mean that the chopped crop is not only processed by friction, but also by cutting and shearing forces. This allows even more intensive conditioning of the grain kernels as well as shredding of the stalk material. Compared with conventional corn crackers, the MCC MAX is suitable for a much larger range of chop lengths and dry matter percentages while still achieving excellent conditioning results. The more intensive kernel shredding increases the digestible starch quantity of the maize silage. This allows more milk to be produced from maize silage and the amount of supplementary feed can be reduced.

Photo