MSV

-> 13.–17. 9. 2021

International Engineering Fair

Facts & Figures:

The

International Engineering Fair is the most important industrial fair in Central

Europe, exceeding 1 600

exhibitors and 80 000 visitors every year. More than 50% of the exhibitors

and 16% of the visitors come from abroad.

The

International Engineering Fair is the most important industrial fair in Central

Europe, exceeding 1 600

exhibitors and 80 000 visitors every year. More than 50% of the exhibitors

and 16% of the visitors come from abroad.

The majority of visitors are professionals. Nearly 80% of those in attendance exert influence on business investment, and one third form part of the top management of their firms.

All key fields of machinery and electrical engineering industry are represented, with primary focus on machining and forming.

MSV’s spotlight is Industry 4.0 and Digital Factory, i.e. digitisation in production, one of the key trends of the innovation process. Other highlighted topics include the circular economy – management of material resources. This is a current trend which is a high-priority area of sustainable development as industry and trade adaptation will move forward in that direction.

Traditionally, MSV attracts significant media attention, with more than 260 journalists attending. One unique component of the fair is an accompanying programme that includes specialist conferences, as well as seminars and workshops on current technical, commercial and economic issues.

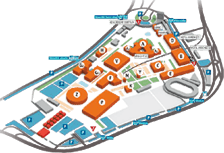

- Full name: International Engineering Fair

- Date: -> 13.–17. 9. 2021

- Venue: Brno Exhibition Centre

- Organizer: BVV Trade Fairs Brno

- Position: No. 1. in Central and Eastern Europe

MSV

7.-11.10. 2013

International Engineering Fair

Gold Medal 2013 - winning exhibits

MCU 1100V - 5X

MCU 1100V - 5X

Producer: KOVOSVIT

MAS, a.s., náměstí Tomáše Bati 419, 391 02 Sezimovo Ústí

Exhibitor: KOVOSVIT

MAS, a.s., náměstí Tomáše Bati 419, 391 02 Sezimovo Ústí

Location: Pav. P, stand 123

Description:

The

multi-functional 5-axis milling machine tool centre with a modular construction

enables complex tooling of wide ranging work pieces from various materials. The

modular nature of the tool centre provides the options to use spindle units

with various properties, to define the size of tool magazines up to holding 360

tools using various clamping systems, to attach a lathe table and adjust the

size of the rotary tilting table. The tool magazine is autonomously controlled

and is characterized by strong rigidity, dynamism and the active thermal

stabilization of the construction. The Faculty of Mechanical Engineering of the

Czech Technical University in Prague and the Faculty of Mechanical Engineering

of Brno University of Technology participated in the project

Smart

autopilot on EPOS airplane

Smart

autopilot on EPOS airplane

Producer: Evektor,

spol. s r.o., Letecká 1008, 686 04 Kunovice, tel.: +420 572 537 428

Exhibitor: Vysoké učení technické v Brně, Antonínská 548/1, Brno 601

90, tel: 541 141 111

Location: Pav.A1, stand 15

Description:

The Smart

Autopilot is an innovative automatic digital flight control system providing

significant flight safety improvements, while maintaining a high level of

pilots’ control autonomy. In cooperation with Evektor, the system was installed

into the futuristic sport aircraft concept SportStar EPOS. As a result of the

development process, a significant synergic effect was achieved by the

unification of the digital flight control technologies with a modern sport

aircraft concept which is powered by an environmentally friendly electrical

engine with characteristic low operating and maintenance cost.

M2 cusing

M2 cusing

Producer: Concept Laser GmbH, An den Ziel 8, 96215

Lichtenfels, Germany

Exhibitor: Misan s.r.o., Ke Vrutici 1795, 28922 Lysá

nad Labem, +420325551440

Location: Pav. P, č.stánku

136

Description:

M2 cusing machine is a metal laser melting system for

production of parts made of stainless hot-work steel, titanium, aluminium and

CoCr alloys, Inconel and precious metals. This additive technology system

utilizes laser to melt metal powder added gradually. It can be used for

production of detailed final components, parts with conformal cooling channels

as well as cast prototypes. This technology can be used in automotive,

aerospace, moulding, medical, dental and jewellery industries.

Innovation consists of

optional quality management system QM Meltpool providing complex production

diagnostics by means of scanning melting process with automatic report of

possible structural faults of produced parts. This function is demanded

especially in aerospace and medical industry.

Jet turbine engine

TJ100S-125

Jet turbine engine

TJ100S-125

Producer: První

brněnská strojírna Velká Bíteš, a. s.

Exhibitor: První

brněnská strojírna Velká Bíteš, a. s.

Location: Pav. V, stand. 037

Description:

The

turbojet engine has been designed and manufactured as a driving unit with the

thrust 1250 N, above all for unmanned air vehicles. The engine is a

single-shaft conception with a single-stage radial compressor, annual

combustion chamber, single-stage axial turbine and exhaust nozzle. The rotor of

the engine is mounted on 2 ball bearings,

lubrication provides autonomous oil system. In the compressor suction,

there is a brush-less starter generator,

which makes it possible to start the engine from the board network and generate

energy during the engine run. Engine control is provided by digital control

system.

Secondary

metallurgy VD / VOD-VI

Secondary

metallurgy VD / VOD-VI

Producer: VÍTKOVICE HLAVY MACHINERY a.s., Ruská 2887/101, Vítkovice, 703 00 Ostrava

Exhibitor: VÍTKOVICE, a.s., Ruská 2887/101, Vítkovice, 703 00 Ostrava

Location: Pav. P, stand 050

Description:

Vacuum

degasser of VD/VOD-VIT type is one of the secondary metallurgy equipment in

which molten metal in the pouring ladle placed in a hermetically closed vacuum

tank is refined under deep vacuum. It can be used in mass-production of steel,

where vacuum refining is followed by

continuous casting or by casting to the

mould, and eventually by subsequent vacuum arc

remelting. In comparison with RH/RH-Ob/RH-KTB type equipment, the advantage of this VD/VOD equipment

is emulsification of treated slag with metal melt during the refining

process, whereas this slag acts as a refining reagent.

Concurrently with

Highlights from companies MSV