MSV

10.-13.10. 2023

International Engineering Fair

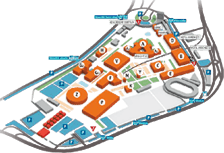

Digital Factory 2.0 will occupy a record-breaking area at the Engineering Fair

Companies will present solutions focused on the digitization of industry in

a special Digital Factory 2.0 exposition, which will be part of the MSV

International Engineering Fair in Brno. From 4 to 7 October, visitors may learn

about latest technologies enabling them to increase the efficiency of the

manufacturing process and achieve energy savings.

"Digitization is one of the main directions of industrial development. This is confirmed by the interest of the companies that have joined the project this year. More than forty companies will showcase their products and services in Hall F and the Digital Factory 2.0 exhibition will thus occupy a record-breaking area so far," stated Michalis Busios, Director of the MSV International Engineering Fair. Siemens has become a Golden Partner of Digital Factory 2.0. Silver Partners are the Team Finland platform and the National Centre for Industry 4.0.

Siemens: solutions for flexible, resilient and energy-efficient production

Rising energy prices, uncertain energy availability, changing customer needs and demands, and the necessity to keep production running at all times. Nowadays, Czech industrial companies must cope with an extremely complicated and unpredictable environment. That is why Siemens will present its solutions under the motto "Flexible, Resilient and Energy Efficient Production". Visitors will also find out how savings can be achieved with minimum investment and practically immediately at an expert conference that Siemens is organising at MSV on 6 October.

Finland at MSV for the first time

Under the banner of Team Finland, Finland is joining this year's Digital Factory 2.0 with the official participation of a group of six innovative technology suppliers and service providers. Finnish companies are trusted by the world's leading manufacturing players from a range of sectors such as automotive, engineering, food, electronics and many others. Visitors to the fair will meet Elisa IndustrIQ, Etteplan, Top Data Science, Unikie, Visual Components and Wapice.

Industrial 5G network and a beer-tapping robot

The opportunity to consult the digital maturity of your own company with attending professionals over a pint of beer tapped by a robot. All this against the backdrop of the Technology Island full of innovation. This is precisely how the National Centre for Industry 4.0 will be presented for the first time at MSV this year. It has installed a Technology Island at the Digital Factory 2.0, which will include a varied exposition based on the installed 5G industrial network and robotic applications that will use it. The exposition takes into account the current situation and the focus is therefore on those solutions that have proven to be effective in practical life to help manage crises. Emphasis is placed on increasing added value, working with data, strategic planning for company development, and sustainability – both as regards materials and energy. The National Centre for Industry 4.0 has invited will be helped in its efforts by these partners: T-Mobile, the RICAIP Research Centre for Advanced Industrial Production, and Česká spořitelna.

Solutions for efficient industry

A number of innovative companies will present their range of products at Digital Factory 2.0. At the 4dot stand, you will learn about technical diagnostics and technology monitoring, and you will see, for example, the 4dot SM transformation sensor, which won the MSV Gold Medal last year.

ABRA Software will also present its exposition, showing how to use its information system to bring Industry 4.0 to life in companies. Visitors may learn, for example, how to effectively digitise processes in 10 practical examples or how to automate the entire company from A to Z.

The company AutoCont IPC, which helps Czech manufacturing companies to increase the efficiency and quality of production using industrial IT technology and specialised software systems, will also be featured. Together with its strong partner, SCADA Servis, it aims to offer manufacturing companies comprehensive solutions that enable them to undergo a successful digital transformation.

Smart glasses and the use of augmented reality in the digitization of industrial production will be presented by AYES. At the stand, people can try on various brands of glasses such as RealWear, Microsoft HoloLens, Vuzix, Google Glass, Oculus and more.

The Digital Factory 2.0 will also include a stand of the company Bossard, which will present systems that fall into the field of smart logistics – SmartBin Cloud, SmartLabel Cloud and Smart Factory Assembly.

Also on display will be WebAR CLDXR platform, which allows companies to showcase their products anywhere, anytime through realistic 3D models placed in the real world using only the Internet and smartphones or tablets.

The company dataPartner will also be an exhibitor at Digital Factory 2.0. The focus of its exhibition will be on the presentation of means for production digitization, both at the level of machine control units and at the level of the production information system.

The company Invanta will demonstrate a safety system with the ability to detect dangerous situations around industrial machines with immediate response. Its highly innovative system uses advanced artificial intelligence models with machine learning and the latest hardware for industrial applications.

A new product for advanced vibrodiagnostics called myCMS will be presented by the company mySCADA. It is an exclusively Czech company dealing with visualization of industrial processes.

Pantek (CS), an authorized distributor and provider of comprehensive technical support for the worldwide AVEVA software for industrial automation, will also be presenting itself.

RAYNET will present its online tool for keeping track of business and customers at the Digital Factory 2.0.

Like last year, the companies SIDAT and SIDAT DIGITAL will participate in the Digital Factory 2.0 project this year. Alongside them, the Slovak company SOVA DIGITAL, which is part of the group, will also participate in the presentation this year.

Furthermore, the company Twinzo will present its solution – an accurate 3D live digital twin of a specific object, which can be a house, an office, a factory or even a whole city. The solution allows you to have a 3D model on your mobile phone, tablet or computer and provides access to all the data in real time.

UNIS will introduce visitors to its MES PHARIS system, which provides production control and continuous monitoring of production processes in real time, tracking of production, collection of technological data and as well as their evaluation. All this in line with the principles of Industry 4.0.

Companies such as Act-in CZ, ARiiVA, Eurowater, GE Intelligent Platforms, Gedis Distribution, Leadspicker, NTT Czech Republic, NTT DATA Business Solutions, Optisolutions, Packung, SAP ČR, SmartVision, Smart Product Solution or Thein Digital will also present their products. The co-organizer of the project is the company Cerebrica. The Digital Factory 2.0 will also include, for the very first time, expositions of the Association of Industry and Transport of the Czech Republic and the Electrical and Electronic Association of the Czech Republic. ŠKODA AUTO Pressing Plant will also be present, demonstrating the practical use of a digital twin in manufacturing.

MSV

For Exhibitors

For Media

Partners

Concurrently with

You might be interested in

Highlights from companies MSV